Auto body structural repair is a sophisticated process that goes beyond surface repairs, focusing on restoring vehicles' safety and integrity after damage. Skilled technicians use advanced technologies like CAD software and 3D scanning for precise measurements, then employ techniques such as welding, riveting, and bonding to realign and reinforce key components like frames and panels. This meticulous approach ensures enhanced safety, meets regulatory standards, preserves vehicle quality, and contributes to favorable crash test results. With continuous technological advancements and rising safety standards, modern repair shops utilize cutting-edge tools and methods to achieve superior results that meet pre-accident conditions, with future trends including AI integration, eco-friendly materials, and faster turnaround times for impeccable quality and environmental consciousness.

Auto body structural repair is a critical aspect of modern vehicle manufacturing, playing a pivotal role in ensuring safety and performance. As crash test ratings become increasingly stringent, understanding the fundamentals of auto body structural repair is essential. This article delves into the intricacies of this process, exploring its significance in achieving top crash test scores. We’ll examine best practices and future trends, providing insights into how the industry is revolutionizing auto body structural repair for enhanced safety standards.

- Understanding Auto Body Structural Repair Fundamentals

- The Role of Structural Repair in Crash Test Ratings

- Best Practices and Future Trends in Auto Body Structural Repair

Understanding Auto Body Structural Repair Fundamentals

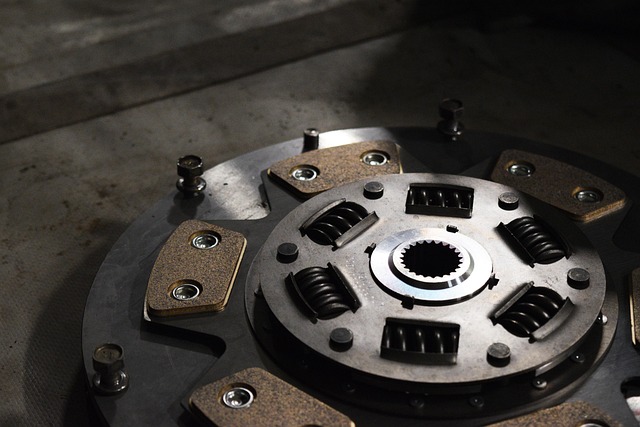

Auto body structural repair is a critical process that involves restoring the integrity and strength of a vehicle’s body after damage. It’s not just about fixing dents or replacing parts; it’s about ensuring the vehicle meets safety standards set by crash test ratings. Understanding the fundamentals of auto body structural repair requires knowledge of various techniques used to realign and reinforce components like frames, panels, and structural members.

This process begins with an assessment of the damage, which helps determine the extent of the repairs needed. Advanced technologies, such as computer-aided design (CAD) software and 3D scanning, play a significant role in accurate measurements and precise repairs. In a vehicle body shop, skilled technicians employ techniques like welding, riveting, and bonding to realign and reinforce damaged areas, ensuring the vehicle’s structural integrity is fully restored. This meticulous work not only prepares the car for recertification but also guarantees its safety and performance on the road. Moreover, when combined with expert fender repair and car paint repair services, auto body structural repair becomes a comprehensive solution that restores both the visual appeal and structural soundness of a vehicle.

The Role of Structural Repair in Crash Test Ratings

The integrity of a vehicle’s structure is paramount when it comes to crash test ratings. Auto body structural repair plays a pivotal role in ensuring that vehicles meet and exceed safety standards set by regulatory bodies. During a collision, the structural framework bears the brunt of the impact, transmitting forces throughout the car. Skilled technicians use advanced techniques and specialized equipment to precisely repair and reinforce these components, maintaining their strength and rigidity. This meticulous process involves aligning panels, replacing damaged parts, and utilizing modern adhesives and reinforcements to restore structural integrity.

Proper auto body structural repair not only enhances safety but also preserves the overall quality and value of the vehicle. By restoring the car’s structure to its original specifications, these repairs contribute to favorable crash test results, ensuring that the vehicle provides optimal protection for occupants in the event of an accident. This attention to detail is especially crucial when considering the advancements in safety technologies and stricter regulations aimed at enhancing passenger safety.

Best Practices and Future Trends in Auto Body Structural Repair

In the realm of auto body structural repair, best practices continue to evolve as technology advances and safety standards rise. Modern crash test ratings demand intricate precision in repairing vehicles, ensuring they meet or exceed pre-accident conditions. Professional collision repair shops invest in state-of-the-art equipment and highly trained technicians to deliver top-notch services. These include advanced robotic welding systems, computer-aided design (CAD) software for accurate measurements, and specialized paint services that match original factory finishes perfectly.

Looking ahead, future trends in auto body structural repair promise further enhancements. The integration of artificial intelligence (AI) and machine learning algorithms is on the horizon, enabling more efficient and consistent repairs. Additionally, sustainable practices are gaining traction, with an emphasis on using eco-friendly materials and reducing waste. As consumers demand faster turnaround times and impeccable quality, collision repair shops will continue to innovate, leveraging advanced technologies while adhering to strict industry standards. This ongoing evolution ensures that vehicle repair services remain at the forefront of safety, efficiency, and environmental consciousness.

Auto body structural repair plays a pivotal role in enhancing vehicle safety, as evidenced by its direct correlation with crash test ratings. By mastering fundamental techniques and adopting best practices, the industry continues to evolve, ensuring cars provide optimal protection in the event of a collision. As technology advances, future trends in auto body structural repair promise even more robust and lightweight materials, further revolutionizing both vehicle performance and passenger safety.